Dowel bar - Purposes and Advantages

Dowel bar - Purposes and Advantages

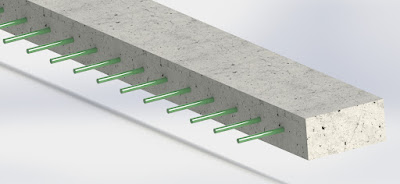

Dowel bars indicate the steel left portion to be joint of any members like slab, column, steps, and so on to transport the actuating load in the concrete individuals. Dowels bars are the steel, rod bar, or rebar that is left according to the measurement of steel.

Dowel bars are round steel that is put across level joints of concrete individuals critically kept as load move factor across concrete joints, it additionally permits movement to act. It very well may be put where movement is intentionally intended for joints of longitudinal.

Dowel bars are of two types:

Stainless steel dowel bar.

Epoxy-coated dowel bar.

What is the use of Dowel Bar?

Dowel bar or steel is used in many ways. Dowel bars are placed at the traverse joints of concrete pavement and must always be parallel to the centerline. Half of the length of this bar is embedded in one of the concrete slabs and the remaining portion is bonded in the other adjacent slab. One end of the bar is kept free for movement during expansion and contraction of the slab due to temperature changes.

The point of dowel bar or steel is given underneath:

The goal of the dowel bar is to advance the presentation of joints.

Dowel bars are saved for the goal of moving load across concrete joints.

It is utilized to decrease corner cracking.

Dowel bars are given for the point of diminishing the joint faulting

It is given for the goal of moving the load starting with one part and then onto the next part like one section to another slab.

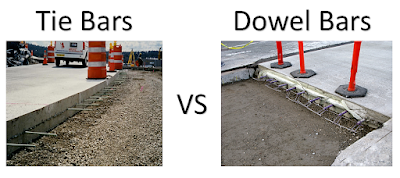

Dowel Bars and Tie Bars

Dowel bars and tie bars can show up the same yet they assume various parts in concrete reinforcement. The two of them altogether further develop the execution of pavement joints and lessen life cycle costs. Tie bars, nonetheless, are distorted rebars that are intended to hold countenances of rigid slabs in touch to keep up with aggregate interlock. Fundamentally, tie bars are not utilized as load-moving gadgets.

Dowel bars are set across cross joints, while tie bars are introduced across longitudinal joints. Dowel bars move load starting with one chunk and then onto the next and tie bars keep paths from detachment and differential diversion. Dowel bars are generally round, smooth, epoxy-coated steel bars and tie bars are deformed epoxy-coated steel. Dowel bars reduce joint faults and corner breaking and tie bars reduce cross breaking.

What are the Advantages and Disadvantages of Dowel Bar?

Some of the advantages of dowel bar that is given beneath:

Dowel bar diverts the separation of the concrete individuals because of the fundamental level movement.

Dowel bar is utilized to broaden the structure effectively little drilling is expected to embed the steel for the extension of the structure.

It works on the exhibition of primary part joints

It builds the underlying cost of the project yet reduces Life Cycle Costs.

Dowel bars build the underlying primary part's life

Dowel bar is utilized to build the load conveying limit of section.

Dowel bar is utilized to reduce deflection and stresses.

Disadvantages of Dowel Bar

Problem during installation.

Poorly compacted concrete around dowel bars.

Outlook

Dowel bars are short steel bars that are introduced in concrete slabs to give a mechanical association that doesn't limit even joint movement. They are intended to reduce joint deflection and stress in the methodology and leave slab by expanding load move productivity.

If you want quality Industrial fasteners for your business, you can call us at +971-506349042, +971 6 575 1335.

Comments

Post a Comment